Support the Timberjay by making a donation.

Babbitt engineer patenting a low cost solution to sulfate pollution

But the region’s mining industry remains cool to the potential

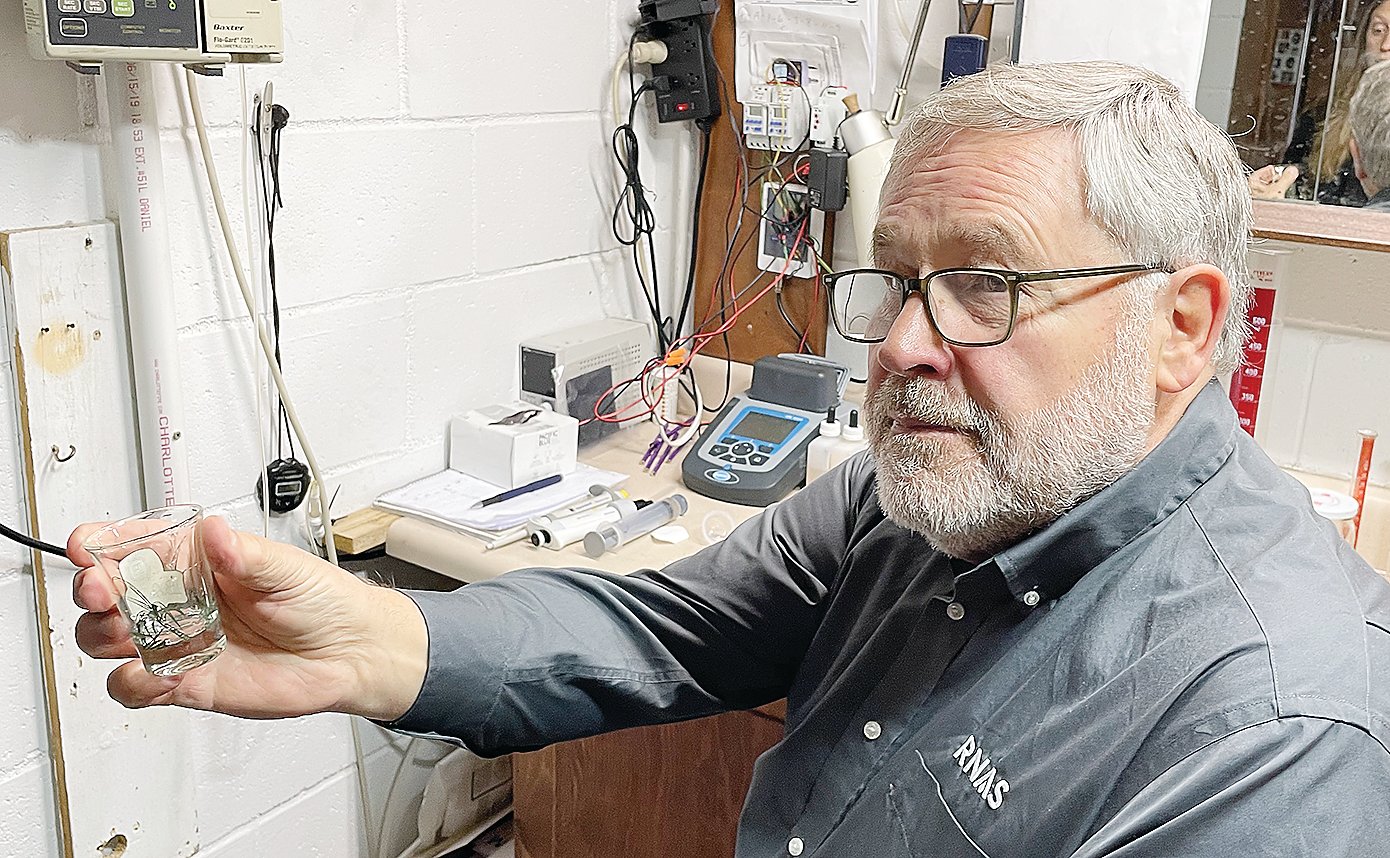

BABBITT— In a makeshift basement laboratory here, Jeffrey Hanson is fine-tuning a process that could turn a cost-effective fix for one of the Iron Range’s biggest environmental problems …

This item is available in full to subscribers.

Attention subscribers

To continue reading, you will need to either log in to your subscriber account, below, or purchase a new subscription.

Please log in to continue |

Babbitt engineer patenting a low cost solution to sulfate pollution

But the region’s mining industry remains cool to the potential

BABBITT— In a makeshift basement laboratory here, Jeffrey Hanson is fine-tuning a process that could turn a cost-effective fix for one of the Iron Range’s biggest environmental problems into a job-producing enterprise. Hanson, a mechanical engineer by training, has been working for more than a decade on better ways to deal with waste and it’s led him to a way to effectively and affordably treat sulfate pollution from Iron Range mines.

It’s a multi-step process, a portion of which Hanson has already demonstrated as part of a pilot study conducted by the University of Minnesota’s Natural Resources Research Institute, or NRRI, the results of which were published in 2017. That pilot study demonstrated that Hanson’s concept could effectively convert sulfate in mine pit water to hydrogen sulfide through the use of what’s known as a “bioreactor.” The process essentially mimics what already occurs naturally in lake and stream sediments, but in a controlled and accelerated way that’s fully contained.

The pilot proved a success, dramatically reducing sulfate levels in the water run through the bioreactors, yet it offered only part of the solution. While sulfate is an undesirable pollutant, hydrogen sulfide is even less desirable. Indeed, it’s toxic, both to humans and to wild rice, a valuable wild food that grows in many lakes and streams in northern Minnesota.

Sulfate discharges, which are a byproduct of iron mining in Minnesota, provide the food source for what are known as sulfur-reducing bacteria, which convert the sulfate to hydrogen sulfide. That connection has been understood by scientists since at the least the 1940s, which is why Minnesota enacted a strict sulfate standard back in 1973 in order to protect the state’s wild rice stands.

While Hanson’s pilot project provided proof of concept that he could convert sulfate to hydrogen sulfide, the study’s authors noted that it hadn’t provided an effective means of handling the even more toxic end product.

While Hanson had proposed using iron to precipitate the sulfide, the study’s authors concluded that: “the associated processes, including sequential chemical addition and mixing, characterization of reaction products, and techniques for collecting slurries, sludge, or precipitated materials, need further development before the methods could be incorporated into large-scale operations.”

Hanson eventually patented the first step in his process and has spent the past four years developing a way to remove the hydrogen sulfide through his company Clearwater BioLogics. He says his new process, which he recently submitted for a federal patent, has proven effective in the lab and results in byproducts, like iron-sulfide and hydrogen, that are both potentially valuable. Now, he hopes to scale up his process and demonstrate its effectiveness using a mine pit lake.

Hanson made a key discovery not long ago that has substantially improved the effectiveness of his process. For some time, he had been using taconite pellets to provide the iron to precipitate out the sulfide. It turns out sulfur likes to bind with metals and when presented with the opportunity, the sulfur in hydrogen sulfide will break its bond, freeing the hydrogen and binding the sulfur with a metal like iron. Hanson initially used taconite pellets to provide the iron for the process, which had only limited success. He eventually realized it was because taconite pellets are oxidized, which slowed the process. When he switched to direct reduced iron pellets, they proved much more effective. At the same time, the DRI nuggets conduct electricity, so he submerged two packets of them underwater and applied electricity. The resulting electrodes helped speed the process considerably.

In the bench tests he’s been conducting for the past few months, he’s been able to take mine-impacted water from Spring Mine Creek near Babbitt and reduce the sulfate level from roughly 350 milligrams per liter to a non-detectable level. And he’s shown he can reduce the resulting hydrogen sulfide from around 100 mg/l to less than four.

An affordable solution?

By rights, Hanson’s process should have the state’s mining industry intrigued, if not excited. Up until now, the only demonstrated treatment for the industry’s sulfate discharges was reverse osmosis, or RO, a highly technical and expensive process that comes with its own waste disposal issues.

Hanson said his process can treat sulfate for roughly one-tenth the cost of reverse osmosis, and possibly less depending on the market for some of the byproducts of the process. Such a potential savings had PolyMet Mining interested in Hanson’s methods, as the company had committed to addressing the high sulfate discharges from several mine pit lakes near its proposed copper-nickel mine. “But they can’t afford to do it with reverse osmosis,” said Hanson. Which is why the company gave Hanson permission to utilize one of its mine pits for his original pilot testing with NRRI.

But the mining industry, which has long had tremendous political clout in St. Paul, has been able to hold off enforcement of the state’s sulfate law for decades, despite pressure from native tribes and the federal Environmental Protection Agency, arguing that any required clean-up would be so costly it could force the shutdown of mines on the Iron Range.

Hanson believes that’s why the mining industry has grown cool to his process and why mining companies are reluctant to give him access to their mine pit lakes to demonstrate his hydrogen sulfide treatment method. “Some of the mining companies really don’t want a low-cost solution,” said Hanson. “Anything costs more than doing nothing, which is exactly what they told me to my face. As long as they can say that RO is the only alternative, they can keep the EPA or the MPCA at bay for years.”

Because Hanson’s hydrogen sulfide removal process has only been demonstrated in his lab, having access to one of the region’s mine pit lakes would provide a critical opportunity to scale up and fine-tune the process and demonstrate its applicability.

While Hanson said Cleveland Cliffs has been more open to his work than other iron mining companies on the Range, he notes the company declined to sell him DRI pellets for his most recent testing. He’s since found another source, but he’s keeping mum on the name of the company.

Waste to resource

Hanson arrived at his concept through a somewhat circuitous route. He’s a guy who likes to connect dots and it was his work more than a decade ago, with a company that was seeking ways of recycling fibers from old carpeting, that he hit upon the potential of using certain types of the fibers, such as polypropylene and polyester, in bioreactors. As he studied their properties, he discovered that they effectively grew loads of bacteria. What’s more the fine fibers could provide an enormous amount of surface area for bacteria to latch onto and grow.

So, Hanson, who grew up on Birch Lake in Babbitt and is well aware of the sulfate problem on the Iron Range, connected the dots and realized that his old carpet fibers might hold one of the keys to solving that long-standing problem.

It’s been well understood for decades that sulfur-reducing bacteria are good at breaking down sulfate under the right conditions. That’s one of the reasons that state regulators in Minnesota and elsewhere have regularly used engineered wetlands, which provide a home for the bacteria, as a passive and low-cost way to reduce sulfates and other pollutants. But those wetlands operate slowly and are ineffective much of the year in northern Minnesota when the wetlands are frozen. And to adequately treat large amounts of sulfate can require enormous wetlands.

Hanson realized that his carpet fibers could recreate the same “habitat” for the bacteria in a much smaller area. So, he designed individual modules, each about 12-feet tall and seven feet by seven feet across and filled them full of his carpet fibers along with some bottom sediments to introduce the bacteria he was looking for. He also provides regular infusions of liquid feed to keep the bacteria healthy.

Each module may occupy very little space, but once filled with the old carpet fibers, it provides approximately 26-acres-worth of surface area for the bacteria to grow. What’s more, the modules are submerged underwater and continue to function well, albeit at a slightly slower pace, even under months of ice cover.

When installed in a mine pit lake, pumps slowly flow the high-sulfate water through the modules. When the water discharges at the end, it’s nearly free of sulfate. The system’s pumps are designed to power with solar panels, so the system can be located in areas without nearby electrical connections.

The process takes occasional maintenance and regular testing to ensure that the modules are doing their job, which means the clean-up of the area’s mine pit lakes would create jobs, dozens of them according to Hanson.

The company’s potential is easy to recognize, which is one reason it was a finalist in the 2018 Minnesota Cup, an annual business start-up competition sponsored by the University of Minnesota’s Carlson School of Business. Hanson said the judges were impressed with the potential of the technology, but pointed out he didn’t have a market for it in Minnesota as long as the state didn’t enforce its own water quality standards.

An ever-growing problem

Hanson said an economically viable solution for sulfate pollution is absolutely needed in Minnesota because the countless mine pit lakes that dot the Iron Range will continue to generate sulfate for decades, even centuries. It’s basic chemistry, notes Hanson. Iron pyrite, otherwise known as fool’s gold, is comprised of a single atom of iron bound to two atoms of sulfur, and it’s found throughout the same rock mined for taconite. As pyrite is exposed to oxygen and water, it’s slowly converted to sulfate. Mine pit lakes become literal sinks for sulfate contaminating groundwater that flows into lakes and streams, or simply discharging at the surface when they overflow.

The vast majority of Minnesota waters naturally contain very low levels of sulfate, typically less than five mg/l. But the water found in mine lakes can be much higher than that, often exceeding 1,000 mg/l and those levels tend to increase over time. Which means reducing sulfate isn’t a temporary clean-up, it’s a massive, long-term process that will require long-term, effective, and low-cost solutions to address. Hanson thinks he’s found an answer, if only the state of Minnesota and the mining industry are willing to ask the question.